How to Make Soap With Wine: Cold Process and Rebatch Recipes

Need a creative way to use up leftover wine that’s sat too long or simply wasn’t to your liking? Try making soap with wine! This post covers two ways to use wine to make homemade soap. The first is a cold process soap that replaces the water with wine in the recipe. The second wine soap recipe teaches you how to rebatch soap, also referred to as hand-milling, to make a second DIY soap.

DIY Wine Soap

When you first start drinking wine, and even once you’ve developed your ever so bougie palette, you tend to end up with bad wine now and then. Sometimes, it’s just not great wine. Other times, it simply may not be to your liking. It could be too sweet or too dry. Or maybe the cork just didn’t seal properly and you’ve got a vinegar brew on your hands instead.

Sadly, there’s just no tolerating a terrible wine. Whether it just tastes awful or it’s started to turn, there’s just no drinking it. Seeing as wine isn’t cheap, I dislike tossing an entire bottle. So, I got creative!

Water is the most common liquid used to make soap. However, you don’t have to use water. Just like making a beer soap recipe, you can also use wine with alcohol for soap making.

Wine soap is an fun way breathe new life into your leftover bottle of wine. Don’t drink vinegar! Learn how to make soap with wine instead. This wonderful soap tutorial guides you through the process with two homemade soap recipes for making DIY wine soap.

My homemade wine soap recipes are a creative way to use up any and all of the leftover wine you may have lurking in your house. The first soap project I share teaches you how to make cold process soap with wine. The second soap making DIY instructs you on how to rebatch that wine soap is make an extra nourishing and hydrating soap bar. Therefore, no matter what type of handmade soap you prefer for your skin care routine, you’re sure to find the perfect solution with these wine soap recipes!

Homemade Wine Soap Benefits

You can use any type of wine you like to make soap. I used white wine to make soap. However, you can also use red wine or even champagne! Like most homemade soap, wine soap also has benefits for skin. They are as follows:

- It cleanses skin to wash away dirt and grime as well as toxins that can clog pores and lead to acne breakouts.

- The polyphenols present in red wine may help reduce the appearance of fine lines and wrinkles to assist in the prevention of premature aging.

- This soap is formulated to extra conditioning so that it nourishes and hydrates dry skin. As it’s not overly cleansing, it won’t strip skin of essential oils that can leave it feeling tight and dry.

- Wine contains natural sugars that make soap extra bubbly. So you’ll enjoy a nice lather when using this soap.

- When making red wine soap you’ll also enjoy the benefits of the antioxidants resveratrol and tannin naturally present in the wine. These compounds fight free radicals that cause signs of aging. They may also help to restore collagen.

Cold Process Wine Soap Recipe

First up is my recipe for how to make wine soap with lye. Just like making homemade beer soap, you do need to take a few extra precautions when you learn how to make wine soap. First and foremost, you need to make sure you’re starting with icy cold wine. Therefore, you should freeze the wine in a container in your freezer the same way you would if you were making a fresh goat milk soap recipe and freezing the milk. You should then mix the lye and wine together in a sink or other contained area in case the lye and wine mixture volcanoes.

My wine soap recipe is not ideal for beginning soapmakers. If you’re looking for a beginner cold process soap recipe, then be sure to check out this DIY for making grocery store soap. It’s an easy and affordable recipe for lye soap if you’re just getting started.

I also recommend that you refer to these instructions on how to make lye soap here if it’s been some time since you’ve made cold press soap. This overview of cold process soapmaking is a great refresher to remind you important safety precautions to take when making homemade soap such as wearing goggles and using a stainless steel or heat safe container to mix the ingredients. It also provides guidelines for making any changes to the recipe.

My cold process wine soap recipe yields 10-12 bars. Each individual soap bar will weigh around 4 oz. each. I made my wine soap using this DIY wood loaf soap mold. However, you can use another mold with similar dimensions. If you don’t want to line the loaf mold for this project, then I recommend using a silicone loaf soap mold.

Following is my recipe for making cold process soap with wine.

Cold Process Soap Ingredients:

These are the ingredients you need to make lye soap with wine. These ingredients include both the soap making fats (carrier oils and butters) and the alkali (lye or sodium hydroxide) necessary for making homemade lye soap. Without fats and alkali, you can’t make true soap. When combined, these ingredients go through a chemical process called saponification. During this process, all of the lye solution is used to convert the fats into soap. Once the process is complete, there is no more lye left in the final bar.

Soap Making Fats

This is a palm free soap recipe. Therefore, I used lard rather than palm oil to make this cold process wine soap. These are the fats necessary to complete this DIY soap project:

- 12.6 oz. lard: Lard is used in lieu of palm oil in this recipe. It makes the final bars hard and adds skin conditioning properties.

- 7.2 oz. refined (76° melt point) coconut oil: Coconut oil is used in this citrus cold process soap to boost the lather. It also helps to create harder homemade soap bars. I used a higher percentage of coconut oil to formulate my DIY citrus soap due to the high volume of mango butter also included in the recipe.

- 5.4 oz. castor oil: Not only does castor oil add skin conditioning properties to soap, it also helps to create a stable lather that is low, dense, and creamy in texture.

- 5.4 oz. rice bran oil: This soap making oil is similar to olive and is often used to reduce the cost of making soap. Like olive oil, it adds skin conditioning properties to the bars.

- 5.4 oz. pomace olive oil: I love using pomace olive oil as it is more affordable than the virgin version. Additionally, pomace olive oil tends to trace faster than the other types available. It also helps to create a hard bar with a gentle, stable lather. Like some of the other ingredients used to make this orange citrus soap recipe, it also has moisturizing and skin conditioning properties.

Wine-Lye Solution

To make the lye-solution for this wine soap, you will use wine to dissolve the sodium hydroxide. In this instance, the wine is used in place of the distilled water normally used in soap making. Make sure the wine is icy cold, but not frozen solid, before getting started as it has a tendency to volcano. As such, I don’t recommend that you use room temperature wine for this project.

TIP: Pour the wine into ice cube trays to freeze. This will help to simplify the process as you don’t want to freeze the wine in the bottle.

These are the amounts of wine and lye needed to make this DIY soap:

- 11. 8 fluid oz. cold wine

- 4.7 oz. lye/sodium hydroxide

Added At Trace

If desired, you can scent this cold process soap recipe. To do so, add the fragrance oil in the amount below at trace:

- 2-2.25 oz. fragrance oil

Soap Making Tools and Supplies

In addition to the ingredients needed to make wine soap, you will also need several tools and various equipment to get started. Here are the additional tools you’ll need:

- Digital scale: A scale is used to weigh all of the ingredients for this summer soap recipe and the essential oil scent blends.

- Digital laser thermometer: You need a thermometer so you can accurately judge the temperature of both the lye-water and soap making oils before you mix them together.

- Immersion blender: Also known as a stick or hand blender, this tool makes it quick and easy to mix your scented summer soap and bring it to trace.

- Loaf soap mold: I used a simple wood loaf mold to mold my homemade soap. However, you can also use a silicone mold. The mold should be able to hold a 3 lb. batch of soap.

- Goggles: Protective eyewear will prevent damage to your eyes if the soap batter or lye-water is splashed or spills.

- Gloves: Nitrile gloves also protect hands from accidental burns that can occur when working with lye.

- Pitchers and measuring cups: You’ll need a heat safe pitcher or container to mix your lye-water in as well as to weigh out the soap making ingredients.

- Large mixing spoons: I use a long plastic spoon, like the wooden ones but plastic, to mix my lye water. I also use a heavy duty metal spoon to scoop out semi-solid oils and butters.

- Spatula: A spatula makes it easy to get all of the soap out of the pot and into the prepared soap mold. It is also used to smooth down the layers and tops of soap.

Cold Process Soap Recipe Notes:

Most of us have a zillion different soap molds for making soap. If you need to resize this soap batch to fit an existing mold, you’ll find the information you’ll need to do so below. This criteria is also helpful if you want to further customize this wine soap recipe.

- The water (or liquid content) of this recipe was calculated at 33% of the oil weight. (The oil weight is the total amount of all the carrier oils and butters used to make soap.)

- To make an extra nourishing and hydrating soap bar, I used 8% superfat. You can reduce this amount to 5% if you prefer a more cleansing soap bar.

- The scent for this homemade soap recipe is calculated at 1 oz. fragrance oil per pound of soap. Keep in mind, however, that some fragrance oils have a lower usage rate than others. So be sure you aren’t exceeding the recommended usage rate for the scent you choose. This goes for essential oils as well.

- The lard in this DIY wine soap accounts for 35% of the oils in this recipe. The coconut oil at 20% and the castor, rice bran and olive oils at 15% each.

- This is a palm free cold process soap recipe. However, if you want to make an all vegetable soap you can substitute the lard with an equal amount of palm oil. In doing so, you will also need to adjust the lye to 4.8 oz. The olive and rice bran oils can easily be substituted in all or part with canola and/or grape seed oil.

- If you want to rebatch this homemade soap after it’s made to add some extra goodies, then omit the fragrance oil when making this soap batch. You will then add 1 oz. of fragrance when you rebatch or hand-mill the soap after unmolding. You can find my rebatch wine soap recipe after the instructions for making cold press soap.

How to Make Wine Soap (Cold Process Method)

When making soap, be sure to do so in a safe area where you won’t be disturbed by small children or pets. Also be sure to start with a clean workspace. Then gather together the ingredients and supplies to you need to started.

Once you have everything in order and ready to go, here is how to make soap with wine using the cold process soap making method:

1. Begin by measuring out the chilled wine of your choice in fluid ounces. I used a local white wine for my recipe.

2. Pour the icy cold wine into a heat safe pitcher and place in the sink.

3. Now use a digital scale to out the lye.

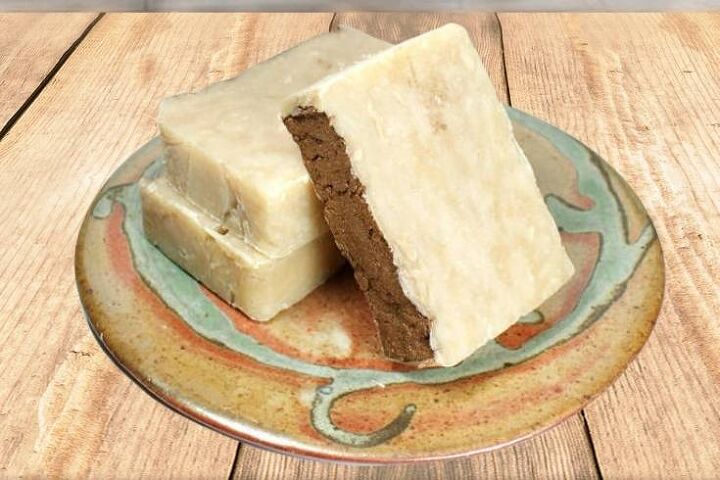

4. Pour the lye, a little at a time, into the wine. Stir well after each pour until the added lye is fully dissolved. Don’t rush it and practice patience. It will seem like there’s not a huge reaction at first. However, the wine will go from yellow to orange at which point my wine boiled then turned a dark brownish-orange. Once you’ve added all the lye and it’s fully dissolved in the wine, set the lye solution aside to cool.

5. Continue with the soap making process by weighing out the soap making oils. Then combine the ingredients in a stainless steel pot.

6. Place the pot on the stove over medium heat to melt the ingredients. Heat the fats (oils) until melted.

7. Once all the ingredients have melted and are liquified, remove them from the heat source. Then set the pot to the side to cool.

NOTE: After both the lye-water and oils have cooled to 90°-95°F you’re ready to mix the ingredients together to make soap. The wine in this recipe does seem to increase trace. So, if you’re using a fragrance oil you may want to mix it into the oils before adding the lye solution. If you’ll be rebatching this soap later, or want an unscented soap, then you don’t need to add the fragrance oil.

8. When the lye solution and oils are the same temperature, slowly pour the lye-wine solution into the liquid oil. Use an immersion or stick blender to mix the two together. Continue blending until you reach trace.

9. If you did not add the fragrance to the oils prior to mixing, add the fragrance oil at a light trace. Then mix again to combine.

10. Now pour the soap into your prepared mold. If you’re using a wooden loaf mold to make soap, you need to line the mold before pouring. You can do this with parchment paper or a small office trash bag. Silicone loaf soap molds do not need to be lined.

11. After 24 hours unmold the cold process wine soap and cut it into bars. Allow the homemade soap bars to cure for 4-6 weeks before use.

TIP: If rebatching the cold process soap loaf, grate the soap right away. I recommend wearing nitrile glove s for this step as the soap may still be going through the final saponification process. Otherwise, wait three days before grating the soap with a cheese grater. At this time, there should no longer be any lye remaining in the soap loaf.

Rebatch Wine Soap Recipe

My dad and son love when I take my cold process soap recipes and rebatch them. Rebatching soap is an easy way to add some extra love — what I like to call moisturizing skin care properties — to your handmade soaps. As pretty much everyone in my family has very dry skin in the winter, adding additional ingredients to cold process soap after it’s been made is an easy way to make it extra conditioning.

Rebatch soaps, also referred to as hand-milled soaps, are created by rebatching or handmilling unscented (or leftover) soaps on the stovetop or in an oven. This is done to add scent and color, conditioning skin care ingredients or to salvage a botched cold process soap batch. Typically one makes hand milled soap by grating an existing soap bar, then mixing it will milk or water. Once the soap melts, other ingredients can be added to customize the fragrance, color or other properties of the soap.

Rebatching soap is an easy way to learn how to make custom natural soaps. The process is easier than making soap completely from scratch in which you combine lye and soap making fats. It’s also a safer process for anyone who has pets or small children in the home. You can learn how to make hand milled soap here. Or check out this other tutorial on how to rebatch soap.

My rebatch wine soap recipe incorporates additional ingredients such as coconut water, cocoa butter and aloe vera gel to give the bars extra skin nourishing and hydrating properties.

If you want to rebatch the cold process wine soap you made, simply grate the soap with a cheese grater after unmolding the loaf. Then combine it in a stainless steel pot or double boiler with the additional ingredients called for in the recipe.

Alternately, if you don’t want to make cold process soap at all, you can also make wine soap using the same recipe and directions. To do this, start with three pounds of rebatch soap shreds or grated unscented cold process soap. Use this in place of the wine soap called for in the recipe. Then replace the coconut water with wine.

Hand-Milled Soap Ingredients:

These are the ingredients need to make hand milled wine soap:

- 3 lb. loaf of cold process wine soap, grated (recipe above) or rebatch soap shreds

- 1 oz. fragrance oil, optional (if loaf is unscented and a fragrance is desired)

- 1 oz. pure coconut water (not from concentrate)

- 1.5 oz. aloe vera gel

- .25 oz. beeswax

- 1 oz. cocoa butter

How to Make Soap with Wine (Rebatch Method)

Follow these instructions to make soap with wine by rebatching soap with additional ingredients for skin:

1. Combine the grated wine soap into a large pot or double boiler on the stove.

2. Weigh out the coconut water, aloe vera gel, beeswax and cocoa butter.

3. Then combine the added ingredients with the grated soap. Heat the soap and additives over medium-low to low heat, stirring often to avoid scorching.

4. Once the soap and the added ingredients have melted, add the fragrance oil if desired or omitted from the previous cold process wine soap recipe.

5. Mix well to combine.

6. Now pour the soap batter into your prepared mold. You may need to use a spoon or spatula for assistance with this as rebatch soap is thicker than cold process soap batter. In a lot of ways it is similar to the appearance and consistency of hot process soap.

TIP: In this instance, you can use the same mold that was used to make the cold process wine soap recipe.

7. Allow the soap to harden two to three days.

8. Then unmold and cut the soap into bars. Allow the soap to cure 4-6 weeks. This allows the soap to finish curing.

NOTE: If you used handmade soap or soap shreds that had previously been cured, you can shorten this time frame. Simply allow enough time for all the excess water to evaporate from the bar before use. This creates a harder bar that will last longer in the bath or shower.

How to Make Colored Soap

If you’d like to make colored soap, no problem! I made a white wine soap recipe. Therefore, the final soap bars were a light tan. This means it will be easy to add a custom colorant to the soap.

If you use red wine to make soap, then you may discover that your red wine soap recipe produces a darker colored soap bar. This doesn’t mean you can’t add a color to your wine soap. It simply means that you’ll want to choose a shade that complements that tone. Alternately, you may need to lighten the soap by adding titanium dioxide to the mix.

To color the cold process wine soap recipe, you may use 2 teaspoons of mica powder or an ultramarine or oxide pigment powder per pound of soap. Mix the powdered colorant into the soap batter once it reaches a light trace.

If you’re looking for an authentic wine color for your homemade soaps, Brambleberry sells a beautiful merlot sparkle mica that you can use to color this wine soap recipe.

I hope you enjoyed this tutorial on how to make soap with wine. If you’d like to try more of my homemade soap recipes, then be sure to check me out on Facebook, Twitter, and Instagram. You can also follow my Pinterest boards for more creative soap making ideas and DIY’s.

Enjoyed the project?

Suggested materials:

- Wine

The author may collect a small share of sales from the links on this page.

Comments

Join the conversation